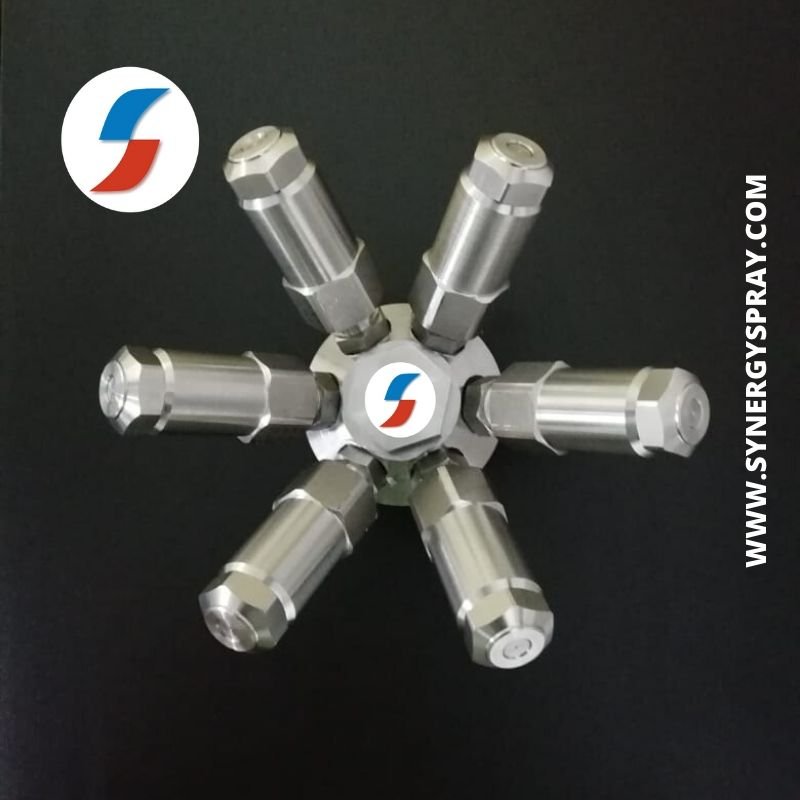

At Synergy Spray Systems, We manufacture wide range of spray Nozzles for commercial and industrial purposes. Our customers include the engineering, Coal Mine, Power, Dust Suppression, food processing, chemical and petrochemical companies in South India. Whether big or small our customers can rely upon our combined experience to ensure the correct nozzle is selected no matter the application.

All our products are sourced from high quality suppliers but what our customers really value is our technical expertise. We make any spray application project ensuring that correct product selection is simple and hassle free. Also we can normally match nozzles from our ranges with those of competitors.